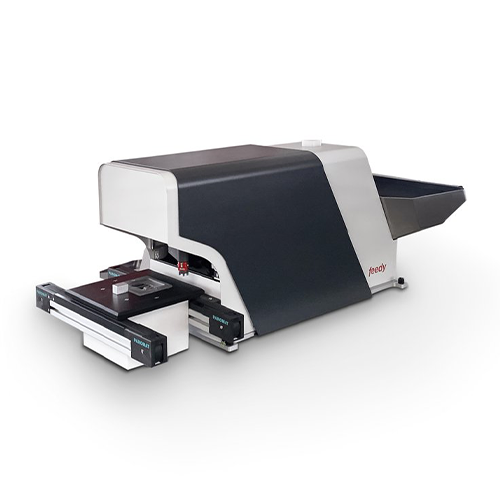

Discover a revolution in intelligent feeding technology with our compact device that integrates all components. feedy offers a unique combination of bulk material separation, integrated image recognition, and robotics. Best of all, feedy is as easy to integrate as a classic vibratory feeder, yet infinitely flexible.

feedy separates parts, recognizes them using integrated image processing, and delivers them in a precisely positioned manner. After a brief training session, users can easily learn to operate and program the system for new parts. feedy comes equipped with its own small robot to deliver parts with exceptional precision.

feedy robotics takes feeding applications to the next level. With its high precision and speed, feedy can pick and place parts with exceptional accuracy. Whether it's small screws, electronic components, or other parts, feedy ensures a seamless and efficient feeding process, solving tomorrow's challenges today.

Technical data:

| Container capacity | 0.3 dm³ |

| Visibility field | 50x67 mm |

| Working field | 34 cm2 (5x6.7cm) |

| Working field displacement | 0.1 mm |

| Repeatability of the feeder platform height on the Z-axis | ± 0.05 mm |

| Maximum weight on the feeder | 50 g |

| Working height | 138 mm |

| Belt height | 17 mm |

| Clearance | 9.7 mm |

| Power | 24 V/10 A |

| Power consumption | 50 W (depending on the mode) |

| Compressed air | - |

| Surface roughness | ± 1.5 mm |

| Container roughness | ± 0.5 mm |

| Intarface | RS232 (DSUB89 female) |

| Drive | 2 brushless |

| Working temperature | 5-45 °C |

| Maximum humidity | 95 % non-condensing |

| Wieght | 7 kg |