The AREX400 is one of the most popular laser marking machines in the manufacturing industry. In many applications, traditional mechanical positioning of parts can be problematic or insufficiently accurate.

AREX400 is one of the most popular laser marking machines in the manufacturing industry. In many applications, traditional mechanical positioning of workpieces can be problematic or insufficiently accurate. In such cases, automatic positioning of the laser project using an advanced vision system proves to be the ideal solution.

A camera integrated with the marking head identifies the relevant element based on the image and then transmits the X and Y coordinates and the angle of rotation to the PLC controller. The controller uses the MOVE AND ROTATE DOCUMENT command (with the specified x, y and angle values) to move and rotate the project within the laser working area.

In some cases, it is possible to connect the camera directly to the marking machine, but most often a PLC is used to manage the marking process, select the appropriate design, and transfer data. Communication between the laser and the controller is carried out via Ethernet TCP/IP, Ethernet IP, or Profinet protocols.

Positioning accuracy depends mainly on the resolution of the CCD matrix and the focal length of the lens, which affect the camera's field of view. In practice, an accuracy of 0.05 mm to 0.1 mm is possible even with affordable cameras and is fully sufficient for most industrial applications.

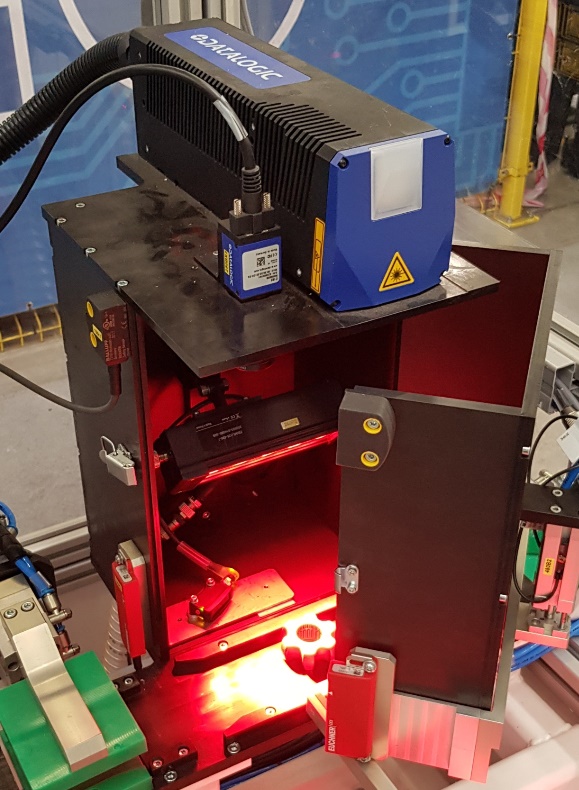

In our laser marking laboratory, we have created a test station for automatic positioning. The application involved precise positioning on small electronic components measuring 2×3 mm, which can change position in tape sockets. Thanks to the use of a 5 Mpx camera, it was possible to achieve repeatable accuracy of 0.5 mm. In a single acquisition, the camera analyzes the coordinates of up to 10 individual details.

The positioning system was also implemented using a P17 smart camera with a resolution of 1.3 Mpx. It enables precise marking on plastic plug connectors, ensuring the right quality in a dynamic production environment.

Another example of application is a configuration using the AREX420 marking machine and the MX-E20 vision system with a 2 Mpx E182 camera. The camera precisely locates one of the “teeth” on an automotive part and enables the feature to be applied exactly in the designated place. In order to improve contrast, background matting was additionally used in the marking machine design.

Please contact us for more information on laser marking.

Contact:

e-mail: piotr.baluta@eltron.pl

tel. +48 664-331-669